Request a Quote

Leave us your details and we will contact you soon.

For Inorganic Samples By High-Frequency Induction Furnace

CSBOX HFA CS Analyzer is used to determine Carbon and Sulfur in inorganic samples like steel ,Iron , ores , finished metals and other inorganic samples.

The analyzer provides simultaneous Carbon and Sulfur determination with minimal sample preparation. It consists of two independent IR cells with a wide measuring range of Carbon and Sulfur. The measuring range of each IR cell is modified to the user’s specific requirement to ensure optimum measurement conditions for each application.

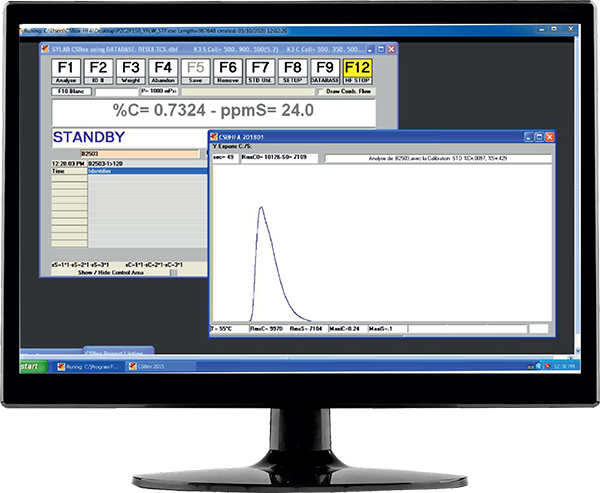

CSBox HFA is supplied with comprehensive software package which includes statistical reports, diagnostics features and other functions.

High frequency induction furnace ensures complete decomposition of samples like Steel, Ores, Cast iron, Refractory samples.

Unique user friendly design of Sylab, where Furnace is Isolated from the infrared analyzer to improve the life of the NDIR analyzer.

Automatic crucible loading with tool free auto cleaning of the combustion tube.

We offer wide variety of certified reference materials with various ranges

We also offer a full range of consumables and accessories such as crucibles, boats, Combustion tube, glassware and other miscellaneous operating accessories.

Updates Soon…

CSBox HFA CS is a computer-controlled instrument used for simultaneous determination of Carbon & Sulphur in a wide variety analyzer & a wide variety of Inorganic samples like steel ,Iron , Refractories, Catalysts & more.

The analyser employs a high-temperature combustion using an induction furnace followed by non-dispersive infrared detection. Sample is weighed (generally 100 mg-200 mg) into a crucible along with a suitable accelerator and placed on the loading pedestal. The sample crucible is automatically lifted into the furnace where eddy currents generate clean, non-contact heat in the sample under an oxygen stream.

During combustion the Carbon & Sulphur present in sample material forms Carbon Dioxide (CO2) & Sulfur Dioxide (SO2).The Unique design of the Analyzer prevents any atmospheric gases to enter combustion zone & vice-versa.

Sample + O2 Heat CO2 + SO2 + H2O

The CO2 & SO2 gases are selectively passed through glass tubes filled with Magnesium Perchlorate to trap moisture. The sample gases free of moisture are passed through two independent Non-Dispersive Infrared Detectors (NDIR) cells.

The Sulphur IR cell measures the concentration of SO2 gas & Carbon IR cell measures the concentration of CO2 gas. The Analyzer converts these values to percentages/ppm concentration.

The CSBox HF analyzer is capable to determine Carbon & Sulfur in various samples matrices

NDIR cells work on the principle that the CO2 & SO2 gases absorb Infrared(IR) energy at unique wavelengths of the IR spectrum

| Furnace | High Frequency Induction Furnace |

| Measuring Range | Carbon: 0.0001% to 100% based on the sample weight Sulfur: 0.0001% to 20% based on the sample weight |

| Detector | Non-Dispersive Infrared Detection |

| Accuracy | ± 1% Relative |

| Sensitivity | 0.1 ppm |

| Analysis Time | 20 Sec to 60 sec |

| Sample Weight | 100 to 200 mg Depends on the sample type |

| Required Chemicals/ Reagents | Magnesium perchlorate (Anhydrone) Glass Wool |

| General Requirements | |

| Ambient Conditions | 15 to 35°C |

| Relative Humidity | 20 – 80% (not condensing) |

| Power Supply | 230V AC ± 10%; 50/60Hz |

| Gases | Oxygen 99.95% purity |